What is Microfluidics?

Microfluidics is the science and technology of manipulating sub-milliliter volumes of liquid in micron-sized structures. Fluids behave differently at this scale, allowing scientist to control liquids in ways that cannot be achieved using conventional methods. Because it is a tool employed in many fields including chemistry, biochemistry, physics and engineering, applications using microfluidics are very diverse ranging from print heads and point-of-care diagnostics, to chemical synthesis and cell-sorting.

|

Miniaturization of processes onto microchips offers many advantages over conventional techniques. These benefits include:

|

Though applications using microfluidic technology are diverse, many have shared experimental components. These include fluid delivery pumps, connectors, microdevices, and detectors.

|

PneuWave Flow and Pressure Control Pump.

|

Fluid Delivery Pumps. Pumps can offer continuous or non-continuous flows and can be based on a variety of different mechanisms including syringe, pneumatic, peristaltic, gravity-fed and electroosmotic. For microfluidic applications special care needs to be taken to eliminate unwanted pulsatile flows. |

PeriWave Flow Control Pump.

|

|

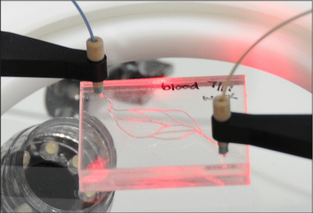

Connectors. Microfluidic experiments require a means of making leak-tight connections between the fluid delivery pump and the microchip, and between the microchip and the detector. The importance of these connections for microfluidics has been often overlooked. Ideally these leak-tight connections are zero-dead-volume, do not utilize adhesives, can be rapidly established, are independent of substrate material, and are non-permanent. |

Rapidly make non-permanent, leak-tight, fluidic connections to any microdevice.

|

|

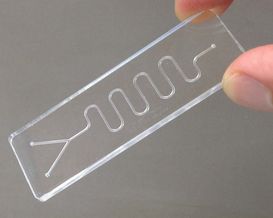

An example serpentine chip.

|

Microdevices.

Microdevices are made from a variety of substrate materials including glass, silicon, plastics and PDMS. Complex architectures of channels, reservoirs, inlet and outlet ports, and other such features are molded, machined or imprinted into the substrate. Substrates are selected based on their optical, surface chemistry and manufacturability properties. |

An example "Y" chip.

|

|

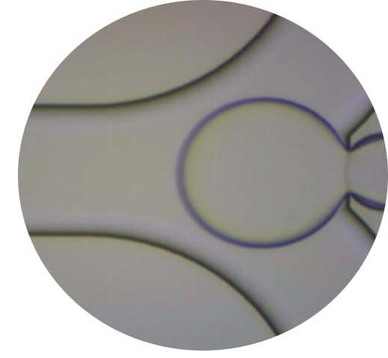

Detectors. Currently the most common detector for microfluidic applications is the microscope. A wide range of upright and inverted microscopes, equipped with transmitted, reflected and/or fluorescent light options is available. A microscope is selected to meet the needs of the specific application. Other types of detectors used in microfluidics include mass spectrometers, UV-vis with diode-arrays, and electrochemical.

|