Degassers

|

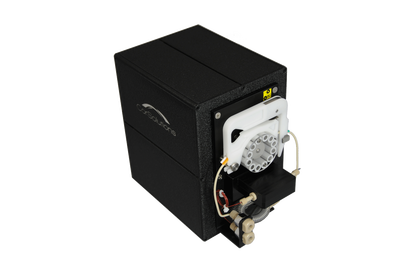

A 2-channel degasser.

|

Removes Dissolved Gases From Liquids

|

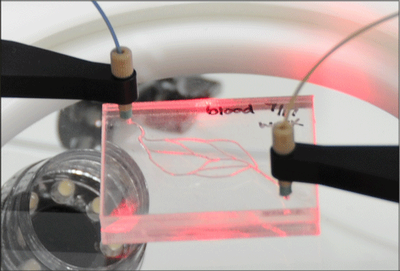

Degassers can be used in-line with the PneuWave fluid delivery pump.

|

Vacuum Degassing Using a Gas-Liquid Separation Membrane

A degassing unit, when installed in-line between the solvent bottle and the fluid delivery pump, offers a facile means to minimize bubbles. The degasser has a short length of polymer tubing through which the solvent flows and through which gas molecules are selectively permeable. This tubing is located in a vacuum chamber maintained by a vacuum pump which is constantly running at a low speed. The unit maintains a vacuum pressure on the outside of the tubing. Dissolved gases migrate across the tubing wall under a concentration gradient produced by the vacuum as the solvent flows within the tubing. By applying vacuum on the outside of the highly permeable membrane, the dissolved gas is removed through the membrane while the liquid remains on the interior. The gases are then expelled from the system. Typically, approximately 50% of the dissolved gas in a liquid must be removed to prevent problems with bubble formation in flow lines. It is not necessary to eliminate all dissolved gas, as it only needs to be reduced to a concentration that is below the saturation point of the mixture.

Other Related Products