How To Avoid Bubbles in Microfluidics

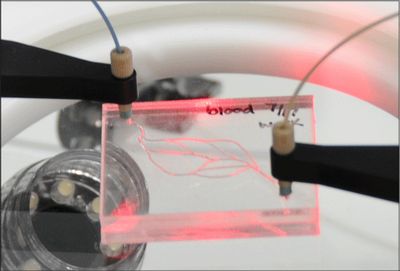

Generally speaking, bubble formation becomes problematic with increasing temperature, decreasing pressure, and mixing solvents. The presence of bubbles in a liquid can compromise experimental outcomes, and microfluidics, which uses small dimensioned channels and tubing, is particularly susceptible to bubbles. Therefore with microfluidics, it is beneficial to consider the issues bubbles can create, along with their cause and how to minimize their presence.

|

|

What Causes Bubbles and How to Avoid Them

|

What Causes Bubbles? |

|

How to Minimize Bubbles |

|

At on-set of an experiment,

liquid must replace all the air in the flow path, and during this process

bubbles can trap or collect in certain regions, making their elimination

difficult. |

|

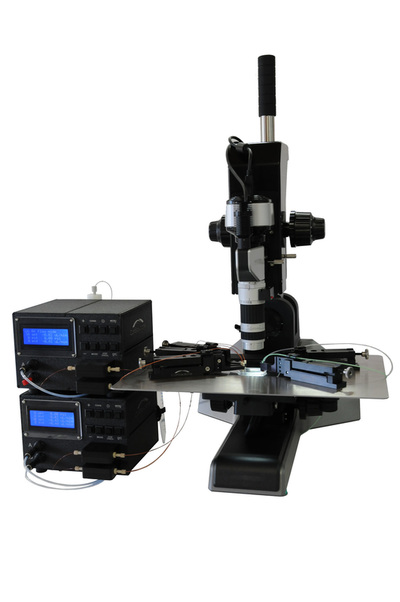

·

Design microfluidic devices without corners, sharp angles

or other geometries which are conducive to trapping bubbles. Design to minimize system dead volume and

use low dead volume CorSolutions’ connectors. ·

Flush system with isopropyl alcohol or a surfactant, such

as SBS, to remove trapped bubbles ·

Using solvent degassed with a CorSolutions’

degasser will gradually dissolve trapped bubbles |

|

When changing liquids air can

be introduced into the system. |

|

·

Use an injection valve to introduce a new liquid which

will keep the system closed |

|

If there is a system leak,

bubbles can be introduced |

|

·

Minimize the use of fittings and ensure the ones that are

being used are not leaking. |

|

Liquids can contain dissolved

gas, which can outgas during experimentation |

|

·

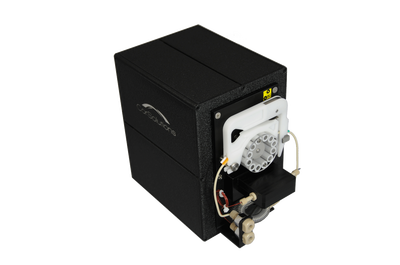

Add CorSolutions’ in-line

vacuum degassing unit |

Benefits

|

|