Microfluidic Connectors

|

|

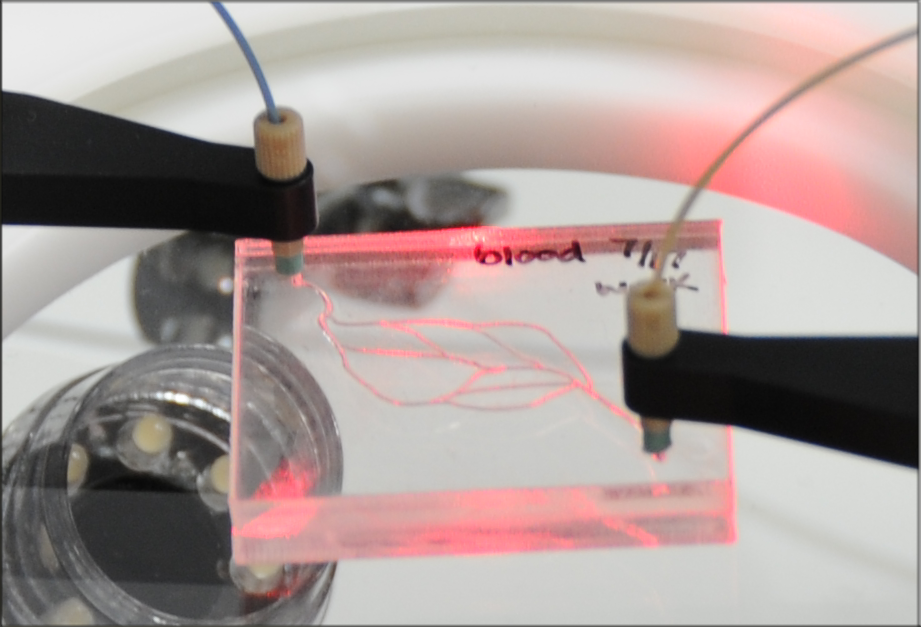

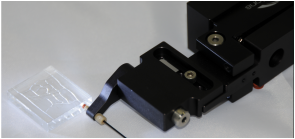

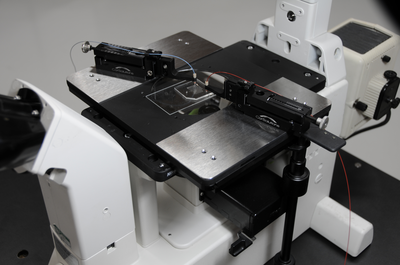

Rapidly make non-permanent, leak-tight fluidic connections on the surface, or side, of a microdevice.

Benefits

|

How it WorksMount

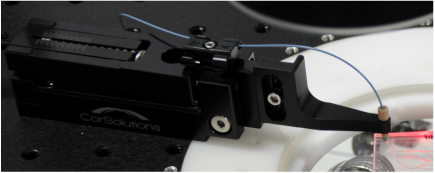

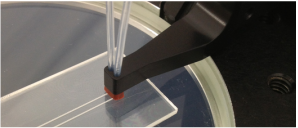

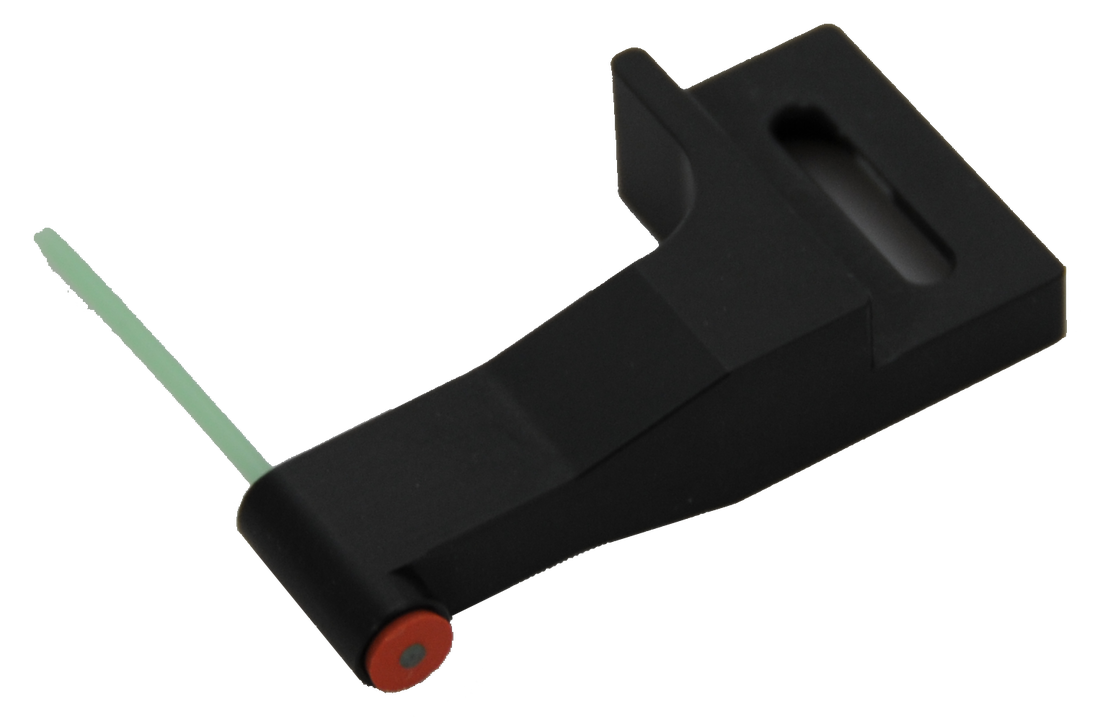

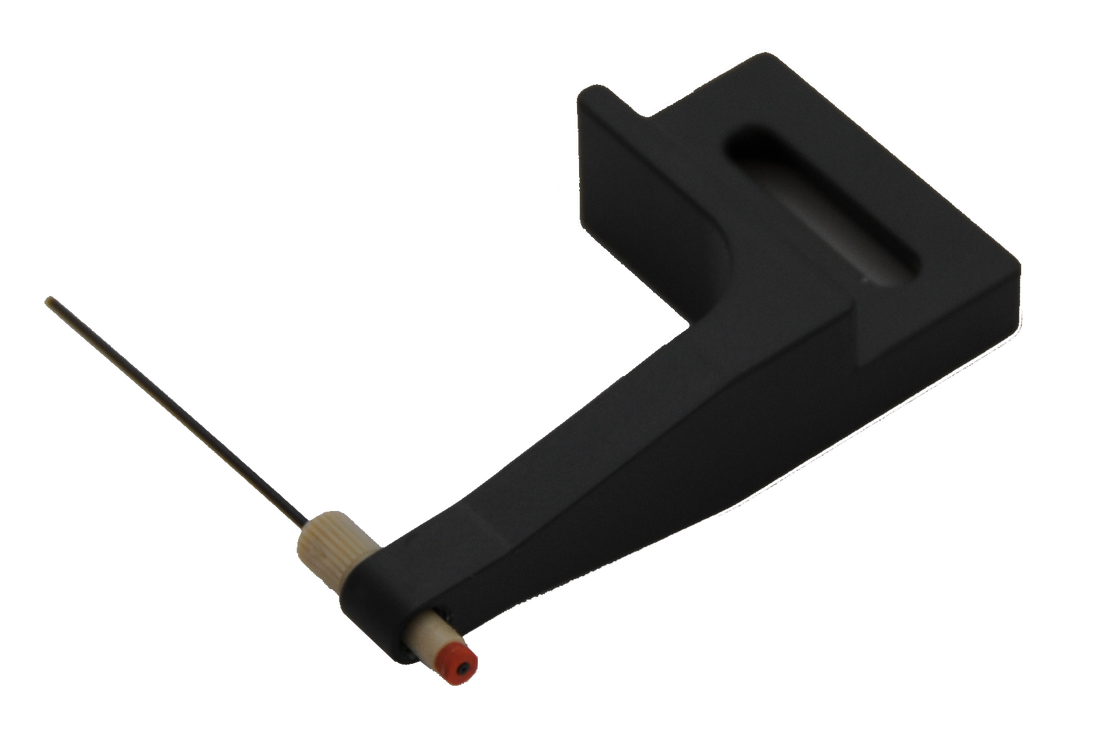

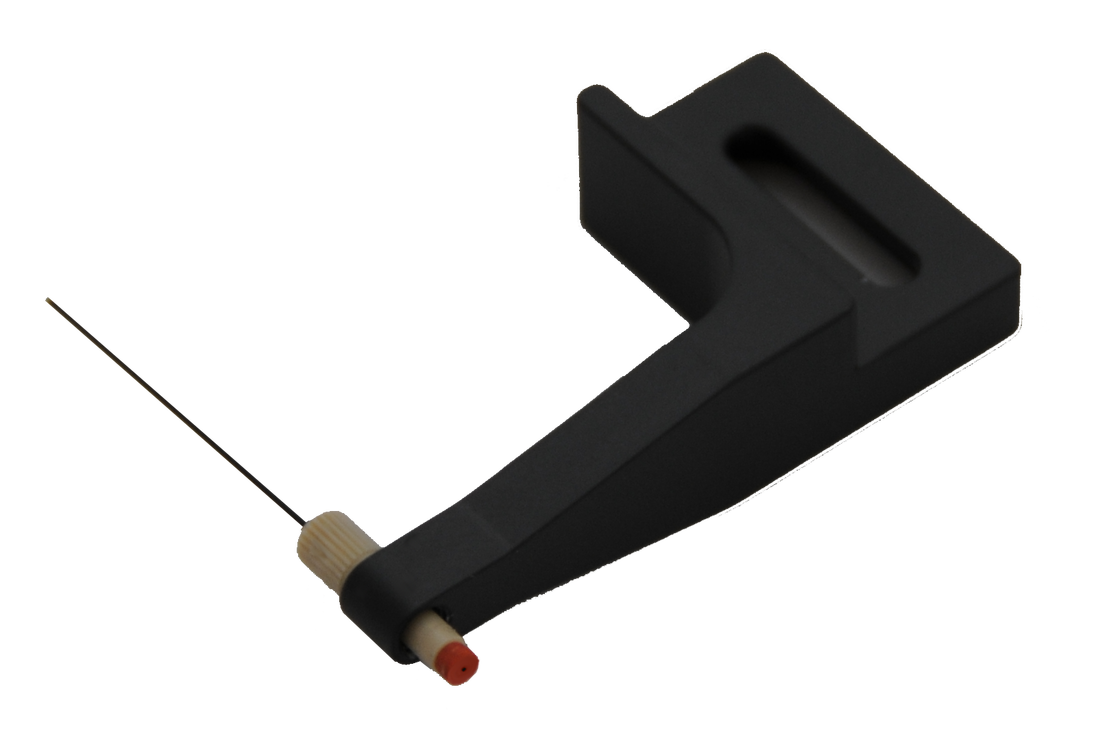

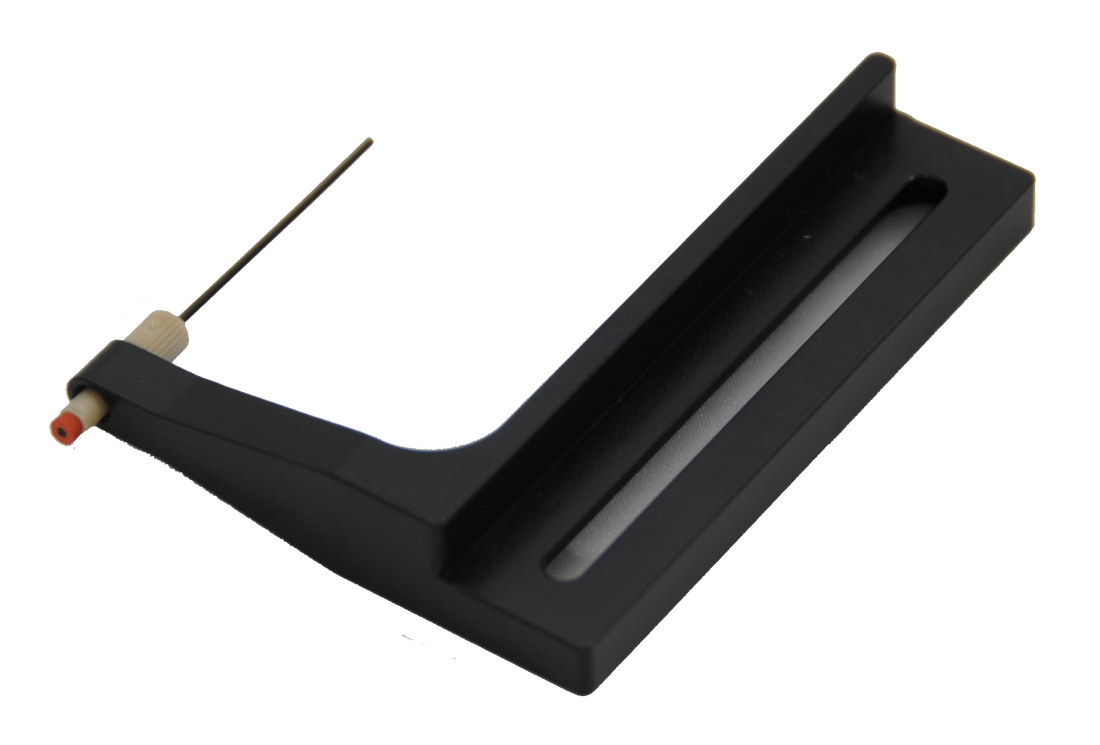

The connectors mount to a flat surface with either a screw (1/4-20 or M6) or a magnet. End Attachment The end attachment portion of the connector is specific for a tubing or adapter size. This attachment is removable and can be easily exchanged. Please see below for example end attachments. Compression Seal The connector makes a compression seal between a gasket, held by the connector arm, and the microdevice. The amount of compressive force applied can be adjusted. Depending on the microdevice substrate material, the compression seal can remain leak tight at greater than 500 psi. |